Sunday, July 31, 2016

ABI Hinge Repair

Friday, July 29, 2016

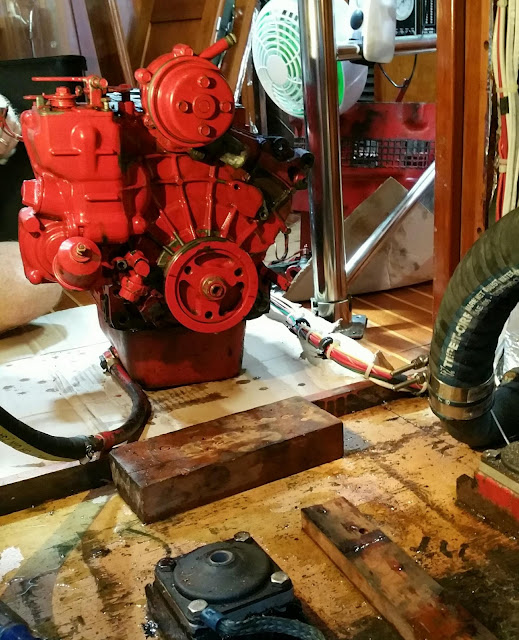

Westerbeke Exploded

Tuesday, July 26, 2016

Location Map July 22nd - August 22nd

Thistle is on the move again! We moved about 1500' from where we used to be. The excitement was almost too much!

When we first arrived here at Sunset Bay Marina they suggested we take mooring #61, #62, or #63. We took #61, and quickly realized it was very far from the dinghy dock. So when we signed up for another month, we asked for a closer spot and got mooring #47.

It's closer to the fuel dock, the dinghy dock, the bridges, and all the other boats, so now we feel like we're really part of the neighborhood.

Friday, July 22, 2016

Bicycling in Stuart, Florida

Nautical But Nice

Tuesday, July 19, 2016

The Fox, The Goose, and The Bag of Beans

Sunday, July 17, 2016

Westerbeke Generator Compression

Saturday, July 16, 2016

Westerbeke Generator Problems

Thursday, July 7, 2016

Still Floating

Thoughts on the Endless Summer

I'm pretty sure a lot of sailors have the dream of going cruising and enjoying an "endless summer" as they hop from one tropical island to the next. They envision carefree days lazing around the boat, swimming in the ocean, snorkeling, drinking sundowners in the cockpit, and working on their tans.

Since we left California in October of 2014 we have been between 9 and 25 degrees of latitude. We have visited Mexico, Central America, Panama, Colombia, many of the Caribbean Islands, and now Florida. For twenty months we have lived in this endless summer and we can tell you this: it's not so dreamy after all.

To save our skin from damage we try to stay in the shade wherever we go. We cross the street to get to the shady side. We wear wide brimmed hats or carry umbrellas. On the rare occasions when we go to the beach, we crawl under the shrubbery to avoid the sun. While the tourists frolic in the blazing sun, we try to stay still and out of the sun.

And then there's the sand and the salt. Don't even get me started on that. We avoid sand like the plague, but we love to swim and snorkel, so keeping salt water from sneaking below is a constant battle. (Except here in Stuart; you couldn't pay me to get in this water.)

Life on a cruising sailboat is rarely carefree because there is so much maintenance just to keep the sun and ocean from destroying the boat. A fair amount of time every day is devoted to fighting corrosion, sanding varnish, scraping the bottom, polishing the stainless, and removing saltwater. When we see cruisers having a sundowner I'm pretty sure they're drowning their sorrows, not celebrating the endless summer.

Don't get me wrong, we have enjoyed our cruising immensely. We've been to some gorgeous places, seen lots of beautiful scenery, had many exhilarating sails, done some amazing things, met some incredible people, and enjoyed every sunrise and sunset along the way, but we've got to get out of this heat.

I'm sure there are some cruisers who feel differently. Certainly if we had air conditioning we'd feel differently. Or if we left our boat and went home for the summer we'd think it wasn't so bad. But we live aboard 24/7/365, so we're here for the long haul. And after almost two years of this endless summer, we are ready for something different.

We'd like to see the change of the seasons. We'd like to sleep under a blanket. We'd like to walk to the store and not be drenched in sweat when we arrive. We'd like to sit on our settees and not worry about the sweat that's dripping down our backs and saturating the fabric. We'd like to, oh, I don't know, maybe just feel a little COOL now and then.

To that end, Thistle will be heading North soon. It will take a while, but we might actually be wearing long sleeves and seeing the leaves change colors later this year. And we can hardly wait.